Lateral flow technology has become a cornerstone in rapid diagnostic testing, widely used in medical, environmental, veterinary, and food safety industries. Central to this technology is the lateral flow dispenser, a precision device that ensures the accurate deposition of reagents and biological materials onto membranes. This article explores the mechanics, applications, benefits, and innovations surrounding lateral flow dispensers in detail.

Understanding Lateral Flow Assays (LFAs)

Lateral flow assays are simple, paper-based devices intended to detect the presence or absence of a target analyte in a sample. They function much like a home pregnancy test, providing results within minutes without the need for complex laboratory equipment.

LFAs consist of several components including a sample pad, conjugate pad, nitrocellulose membrane, and absorbent pad. Each plays a role in the movement and reaction of the sample as it migrates across the strip. The heart of this process is the deposition of reagents onto the strip, a task managed by lateral flow dispensers.

What is a Lateral Flow Dispenser?

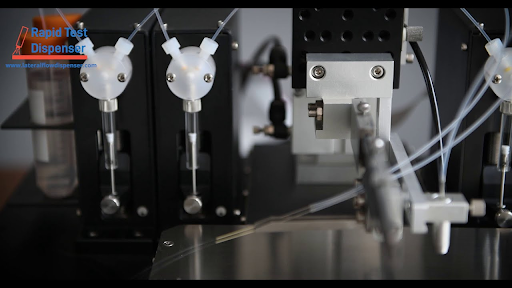

A lateral flow dispenser is a specialized piece of equipment designed to apply precise volumes of liquid reagents onto membranes during the manufacturing of lateral flow assays. These reagents may include antibodies, antigens, or dyes essential to the assay’s functionality.

The dispenser ensures uniformity, reproducibility, and accuracy across thousands of test strips, making it a vital component in large-scale production. In essence, it guarantees that every diagnostic strip contains the exact amount of reagent needed to produce a reliable result.

Components of a Lateral Flow Dispenser

Dispensing Head

The dispensing head is the part of the device that makes direct contact with the membrane. It can range from a single-nozzle design to multi-nozzle systems that deposit multiple lines in parallel. The nozzle’s diameter and structure determine the volume and precision of reagent delivery.

Pumping Mechanism

Dispensers use various types of pumps to deliver reagents, such as syringe pumps, peristaltic pumps, or pneumatic systems. The choice of pump affects flow rate, consistency, and suitability for different reagent viscosities.

Membrane Carrier

The membrane carrier system moves the nitrocellulose membrane beneath the dispensing head at a controlled speed. This ensures consistent reagent application and proper alignment of the test and control lines.

Software Interface

Modern lateral flow dispensers include a software interface for controlling dispensing parameters such as line spacing, reagent volume, dispensing speed, and pump calibration. This feature increases repeatability and simplifies troubleshooting.

Types of Lateral Flow Dispensers

Contact Dispensers

Contact dispensers apply reagents directly onto the membrane using a nozzle or capillary in physical contact with the surface. This type is ideal for high-viscosity fluids and offers excellent line definition but may risk damaging sensitive membranes if not calibrated correctly.

Non-Contact Dispensers

Non-contact dispensers eject reagents onto the membrane from a distance. They reduce wear on the membrane and are suitable for high-throughput environments. Their maintenance needs are lower, and they offer superior precision for low-viscosity reagents.

Multi-Channel Dispensers

For industrial-scale production, multi-channel dispensers can deposit several reagents simultaneously. This is especially useful in multiplex tests where more than one analyte is being detected.

Applications of Lateral Flow Dispensers

Medical Diagnostics

The most common application is in the medical field, especially in point-of-care (POC) testing. Lateral flow dispensers are used to produce tests for conditions like COVID-19, malaria, HIV, and various types of influenza.

Food Safety

In the food industry, LFAs detect contaminants such as mycotoxins, allergens, and pathogens. Lateral flow dispensers play a crucial role in ensuring the reliability of these tests, which are vital for regulatory compliance and consumer safety.

Environmental Testing

Water and soil quality assessments often rely on LFAs to detect pollutants like heavy metals and toxins. Lateral flow dispensers help ensure these test kits provide accurate and reproducible results in field conditions.

Veterinary Testing

Animal health diagnostics also benefit from LFAs. Tests for diseases like avian influenza and foot-and-mouth disease are often manufactured using dispensers for rapid deployment in farms and clinics.

Advantages of Using Lateral Flow Dispensers

Precision and Reproducibility

Automated dispensing ensures that each test strip receives the exact amount of reagent required, eliminating human error and ensuring batch-to-batch consistency.

Scalability

Dispensers enable manufacturers to scale up production without compromising quality. Multi-line and high-speed systems can produce millions of test strips efficiently.

Reduced Waste

Modern dispensers minimize reagent waste by controlling droplet size and delivery rate. This reduces production costs and environmental impact.

Time Efficiency

Automation speeds up the production process, allowing for faster delivery of diagnostic kits in times of urgent need, such as during disease outbreaks.

Key Considerations When Choosing a Lateral Flow Dispenser

Reagent Compatibility

The dispenser must handle the specific chemical and physical properties of the reagents, including viscosity, surface tension, and temperature sensitivity.

Throughput Requirements

Manufacturers must consider how many tests need to be produced per hour or day. High-throughput dispensers are ideal for large-scale operations.

Maintenance and Cleaning

Ease of cleaning is vital, especially when switching between reagents. Dispensers with automated cleaning cycles can save time and reduce contamination risks.

Precision Tolerance

Dispensers should offer low coefficient of variation (CV) in line width and reagent volume to ensure uniformity across all strips.

Innovations in Lateral Flow Dispensers

Smart Dispensing Technology

AI-powered systems now enable real-time monitoring and correction during dispensing. These technologies adjust flow rates based on feedback loops, improving consistency.

Integrated Vision Systems

Vision systems can detect misalignments and defects in real-time, helping manufacturers minimize waste and ensure quality control.

Modular Designs

Modular dispensers allow for flexibility and easy upgrading. Manufacturers can add additional nozzles or replace components without investing in a new system.

Disposable Cartridges

To reduce cleaning time and cross-contamination, some dispensers use disposable cartridges for reagents, improving productivity and safety.

Challenges and Limitations

High Initial Cost

Sophisticated lateral flow dispensers involve significant upfront investment, especially for startups or small-scale manufacturers.

Technical Skill Requirement

Operating and maintaining these machines require trained personnel familiar with both hardware and software components.

Compatibility Issues

Not all membranes or reagents behave identically. Manufacturers must validate compatibility through rigorous testing before full-scale deployment.

Future Trends in Lateral Flow Dispensing

Automation and Robotics

As the demand for rapid diagnostics grows, the push toward full automation will accelerate. Robotic integration in manufacturing lines is expected to become standard.

IoT and Cloud Monitoring

Future dispensers may be connected to cloud systems for remote monitoring, predictive maintenance, and performance analytics.

Green Manufacturing

Eco-friendly dispensers using biodegradable cartridges and low-energy components will align with global sustainability goals.

Miniaturization

Compact, portable dispensers may enable on-site manufacturing or customization of LFAs, opening up new possibilities in remote and resource-limited areas.

Conclusion

The lateral flow dispenser is more than just a machine; it is a cornerstone of modern diagnostic manufacturing. With its role in ensuring precise reagent application, reducing waste, and scaling production, the dispenser continues to evolve alongside innovations in healthcare and biotechnology. As global demand for quick and reliable diagnostic tools rises, advancements in lateral flow dispensing technology will remain pivotal in meeting the world’s testing needs.