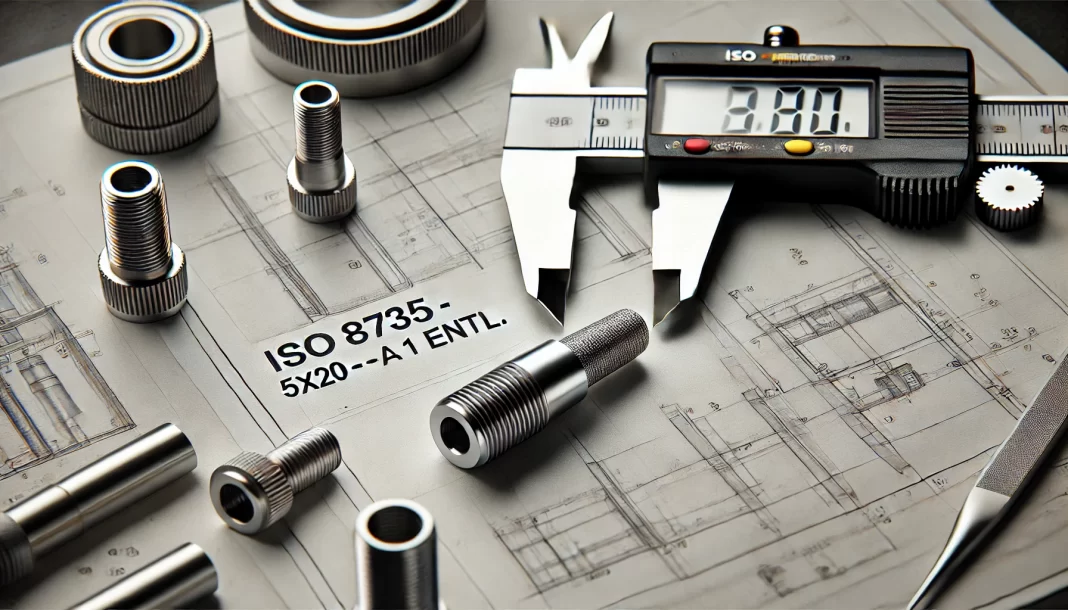

In the realm of mechanical engineering and manufacturing, precision components are crucial for ensuring the reliability and efficiency of assemblies. One such component is the parallel pin with an internal thread, standardized under ISO 8735. This article delves into the specifics of the ISO 8735 – 5×20 – A-C1 entl. pin, exploring its features, applications, and advantages.

What is ISO 8735?

ISO 8735 is an international standard that specifies the characteristics of parallel pins with internal threads. These pins are typically made from hardened steel or martensitic stainless steel and are available in nominal diameters ranging from 6 mm to 50 mm. The standard ensures uniformity in dimensions and mechanical properties, facilitating interchangeability and consistency across various applications.

Decoding the Specification: 5×20 – A-C1 entl.

- 5×20: This denotes the pin’s dimensions, with a diameter of 5 mm and a length of 20 mm.

- A: Indicates the pin type. In ISO 8735, ‘Type A’ refers to pins with a crowned end, through-hardened steel or martensitic stainless steel.

- C1: Specifies the material and hardness class. ‘C1’ typically denotes a specific hardness range suitable for general applications.

- entl.: An abbreviation for ‘entlastet,’ the German term for ‘relieved’ or ‘deburred,’ indicating that the pin has undergone processes to remove sharp edges or stress concentrations.

Design and Features

Parallel pins with internal threads are cylindrical, precision-engineered components designed to maintain accurate alignment between machine parts. The internal thread allows for the insertion of a screw or bolt, enabling secure fastening and easy removal when necessary. The ‘A’ type pin features a crowned end, which facilitates insertion and reduces the risk of damage during assembly.

Applications of ISO 8735 Pins

These pins are widely used in mechanical assemblies where precise alignment and secure fastening are essential. Common applications include:

- Automotive Industry: Ensuring accurate alignment of components in engines and transmissions.

- Aerospace Sector: Maintaining precision in the assembly of aircraft structures and systems.

- Industrial Machinery: Aligning and securing parts in heavy machinery and equipment.

- Tool and Die Making: Providing precise positioning in molds and dies for manufacturing processes.

Advantages of Using ISO 8735 Pins

- Precision: Manufactured to exacting standards, these pins ensure accurate alignment of components.

- Strength: Made from hardened materials, they offer high tensile strength and durability.

- Versatility: Suitable for a wide range of applications across various industries.

- Ease of Assembly and Disassembly: The internal thread allows for secure fastening and straightforward removal when maintenance is required.

Comparison with Competitor Products

While several manufacturers produce parallel pins with internal threads, ISO 8735 pins stand out due to their adherence to international standards, ensuring compatibility and reliability. Competitor products may not always conform to these stringent specifications, potentially leading to issues with fit and performance. Additionally, the use of high-quality materials in ISO 8735 pins offers superior durability compared to some alternatives.

Conclusion

The ISO 8735 – 5×20 – A-C1 entl. parallel pin is a vital component in precision engineering, offering reliable alignment and fastening solutions across various industries. Its standardized dimensions and properties ensure compatibility and performance, making it a preferred choice for engineers and manufacturers worldwide.