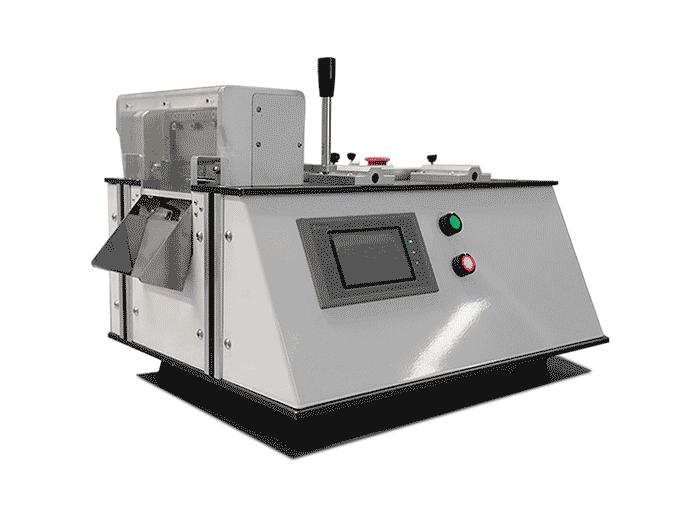

The lateral flow strip cutter has become an essential tool in the development and manufacturing of lateral flow assays, which are widely used in diagnostic applications such as pregnancy tests, infectious disease detection, and environmental monitoring. This specialized equipment ensures precise cutting of the nitrocellulose or other membranes into strips, enabling consistent and reliable performance of the assays. In this article, we’ll explore the importance of lateral flow strip cutters, their working principles, applications, and the features to consider when choosing one.

What Is a Lateral Flow Strip Cutter?

A lateral flow strip cutter is a machine designed to slice large sheets of lateral flow membranes into uniform strips. These strips are crucial for assembling lateral flow assays (LFAs), where consistency and precision directly impact the accuracy and sensitivity of the test.

LFAs are point-of-care diagnostic tools that detect specific analytes in a sample, often through the binding of antibodies or antigens. To ensure these tests work effectively, the membranes on which these biochemical reactions occur must be precisely cut to avoid variability in results. A strip cutter ensures this accuracy, making it an indispensable part of the production process.

The Role of Lateral Flow Strip Cutters in Diagnostic Test Production

The importance of lateral flow strip cutters in diagnostic test manufacturing cannot be overstated. The cutting process is a critical step in ensuring that every strip adheres to the desired specifications. Variations in width, for example, can lead to inconsistent reagent application, affecting the overall reliability of the test.

Here are some key contributions of a lateral flow strip cutter to diagnostic production:

- Precision Cutting

Accurate cutting is paramount in producing lateral flow assays. Strip cutters are designed to deliver consistent results, ensuring uniform dimensions for each strip. This precision minimizes test variability and ensures reproducibility across batches. - High Throughput

In large-scale manufacturing, manual cutting is impractical and time-consuming. Lateral flow strip cutters can process large volumes of membrane sheets quickly, improving production efficiency. - Waste Minimization

Advanced strip cutters optimize membrane usage by reducing cutting errors and minimizing waste. This is particularly important when working with expensive materials like nitrocellulose. - Improved Quality Control

Automated cutting ensures every strip meets stringent quality standards. This level of consistency is critical for producing reliable diagnostic tests, particularly in regulated industries like healthcare.

How Does a Lateral Flow Strip Cutter Work?

The lateral flow strip cutter uses a combination of precision blades and automated controls to cut membranes into strips. Here’s a simplified overview of its operation:

- Membrane Loading

The membrane sheet is loaded onto the strip cutter. This sheet could be pre-treated with reagents or blank, depending on the manufacturing stage. - Alignment

Advanced cutters use sensors or manual adjustments to ensure the sheet is perfectly aligned before cutting. Proper alignment is crucial for maintaining strip uniformity. - Cutting Process

High-precision blades, often made from durable materials like stainless steel, slice the sheet into strips of the desired width. The cutting mechanism may be rotary or guillotine-style, depending on the machine’s design. - Collection

The cut strips are collected in trays or on conveyor belts for further processing, such as reagent application, drying, or assembly into test cassettes.

Applications of Lateral Flow Strip Cutters

Lateral flow strip cutters find applications across various industries, reflecting the versatility of lateral flow assays themselves. Some common applications include:

Medical Diagnostics

Most commonly, strip cutters are used in producing lateral flow tests for medical purposes, such as detecting infectious diseases like COVID-19, malaria, or HIV.

Environmental Monitoring

Lateral flow assays are also used to detect contaminants in water, soil, or air. Strip cutters play a vital role in manufacturing these tests.

Food Safety

In the food industry, lateral flow tests are employed to detect allergens, pathogens, or chemical residues. Accurate strip cutting ensures these tests meet regulatory standards.

Veterinary Diagnostics

Just like in human healthcare, lateral flow tests are used for diagnosing animal diseases. A lateral flow strip cutter ensures that these tests are manufactured to the same high standards.

Features to Look for in a Lateral Flow Strip Cutter

When selecting a lateral flow strip cutter, manufacturers should consider several factors to ensure optimal performance and compatibility with their production needs:

- Adjustable Width Settings

The ability to customize strip widths is essential for producing different types of lateral flow tests. - High Cutting Accuracy

Precision is critical. Look for machines that guarantee minimal deviation in strip dimensions. - Throughput Capacity

The cutter should match the production scale of your facility, whether it’s a small batch operation or a large-scale manufacturing unit. - Material Compatibility

Some cutters are designed specifically for nitrocellulose membranes, while others can handle a variety of materials. Choose one that aligns with your requirements. - Ease of Maintenance

Regular maintenance is crucial for consistent performance. Machines with easy-to-clean blades and straightforward troubleshooting processes are ideal. - Automation Features

Advanced strip cutters come with programmable settings, allowing for automation of repetitive tasks and reducing operator dependency.

Advancements in Lateral Flow Strip Cutters

As technology evolves, lateral flow strip cutters are becoming more advanced, incorporating features that improve efficiency and user experience. Some recent innovations include:

Laser Cutting

Laser-based strip cutters offer unmatched precision and reduce wear and tear associated with mechanical blades.

Real-Time Monitoring

Sensors and cameras integrated into modern machines enable real-time quality checks during the cutting process.

Eco-Friendly Designs

Newer models focus on energy efficiency and waste reduction, aligning with sustainability goals.

Conclusion

The lateral flow strip cutter is a cornerstone of lateral flow assay production, ensuring the accuracy, efficiency, and reliability of diagnostic tests. From medical diagnostics to environmental monitoring, the role of these machines spans a broad spectrum of applications, reflecting their importance in modern healthcare and beyond.

Investing in a high-quality lateral flow strip cutter is essential for any manufacturer aiming to produce consistent and reliable lateral flow tests. By incorporating the latest advancements in automation and precision, these machines continue to push the boundaries of diagnostic technology.